The plastics machining process we propose and create can be achieved not only in cold, but also in heat.

We develop our own products, but we can also work according to the clients’ documentation, with a professional team who always applies to attaining all the products within quality and time parameters.

We assure the assets of our ordered products and we take active part in the final customization of packaging and delivery.

Bending and cold forming

The cold plastics bending and forming equipment is one of the most performing, with a high machining capacity. We also dispose of great storage space for this kind of products.

Plastics extrusion process

On the extrusion lines big series of products from different materials can be processed:

- hard PVC;

- plastified PVC;

- PE;

- PP;

- ABS.

Thanks to the advantages of the new plastics used and the expertise we have, but not last thanks to the continuous infrastructural modernization in the area of networks of water supply, draining stations and sewage, the extrusion operations for rigid or ductile tubes, screwed or smooth, with application in the most diverse activity domains, industrial or civil, has developed substantially.

Plastics injection;

Due to the massive implementation of the plastics injections in the light industry and other branches for the great temperature fluctuation, shock or exterior acid products, this industrial area has developed very much.

These are only a few of the advantages of the plastics products usage and this is the reason we have come up with a qualified team of experts, adjusters and assemblers exceptionally fit in this branch.

The parts we inject are completed with the help of the casts that our partners make available. We also produced some parts with our own casts. We can also assure through our company all the inspections and repairs that the casts need.

Some of the materials we use:

- PP;

- PC;

- PS;

- ABS;

- PC/ABS;

- POM;

- PA 6 30%GF

- PA 6.6

The injection machines we use in the production are effective, up to date and from the following brands: DEMAG, ENGEL, NEGRI BOSSI and KRAUSS MAFFEI

Parts

With the machineries and our experts we provide:

- high quality products;

- flexibility to our clients’ production needs;

- high productivity and settled quality;

- a vast range of closing and injection units blend;

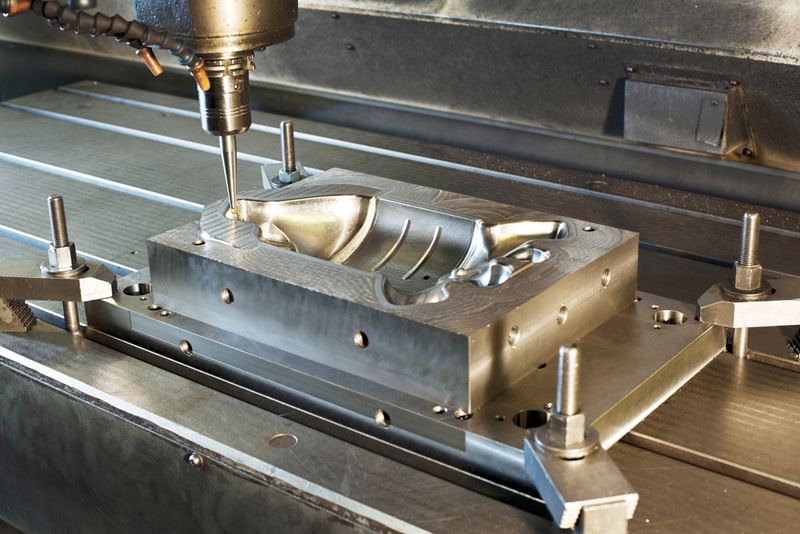

Casts design and production

Our expert team is always available to you to help your ideas become a reality. We also manufacture casts for our own products.

Our workshop manufacturing network-best quality materials from which we produce the casts and tools for delivery-encompasses an entire technological chain: from project consultancy and design to injection of extrusion cast manufacturing.

The machining centers we own within our network are one of the most effective starting with the design programs- CATIA V5-and continuing with the machineries that process the materials. We collaborate with partners that provide us the best quality cast heat treatment.

Assembly processes:

For the solutions we grant you to be complete, we add value to our semi manufactured products, thus combining all the necessary parts in our workshop to liven up the final product.

We manage a young and motivated team, who is always ready to develop your projects concerning installation and assembly of the final or semi manufactured product that build up a complex piece.

The assembly and fitting operation consist of more activities, simple or complex and take off in a transparent process so that you, thanks to the program set up in the company, can permanently watch the development of the entire project.