The mechanical processing that we offer to our clients is divided as it follows:

The mechanical processing that we offer to our clients is divided as it follows:

Cutting process – operation destined mainly to raw parts with complex structures and shapes.

Cold forming and stamping – operation appropriate to the parts obtained from semi-manufactured products.

Our team adds value to the projects through constant engagement in developing the material basis of the production units.

We also dispose of heat treatment suppliers that we add to our services like: nitration, cementation, tempering, annealing, abatement. All the products are accompanied by a hardness analytical report.

During the cutting process, in which we handle steel and stainless steel, the following operations are included:

Laser cutting on numerically control machine tools:

Minimal and maximal bulkiness of the work bench:

- carbon steel: 0,2 – 20 mm;

- stainless steel: 0,2 -12 mm;

- aluminium alloy: 0,5 – 8 mm;

- working area(effective dimension of the work bench): 3000 x 1500 mm (maximum extent of the tools)

- cutting precision: +/- 0,1 mm

- laser cutting center for metal sheet and LT Combo Fiber, 3000 W, BLM profiles

“Abkant” Bending:

Possible manufacturing techniques:

- press force: 1300 kN;

- length bending: 3000 mm;

- pillar gauge: 2,690 mm;

- maximal table dimension/cluster distance-735 mm;

- effective input area height-615 mm;

- working height-1095 – 1115 mm;

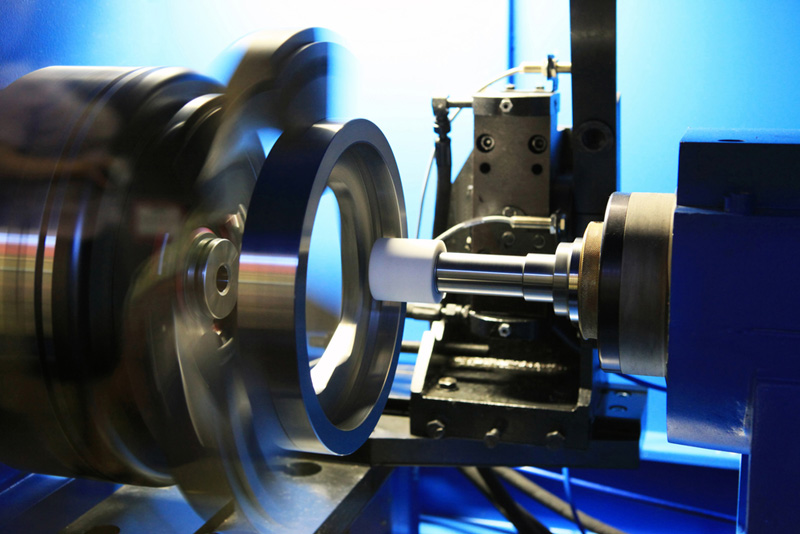

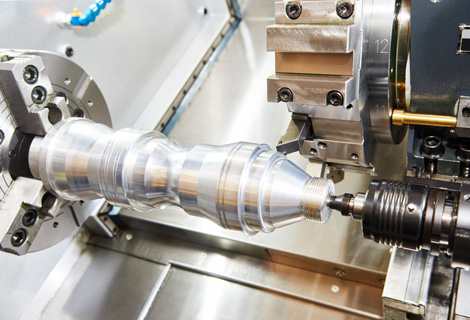

Lathe

- the lathe machining is carried out on different materials(stainless steel, brass, aluminium-steel, cast iron, moulding material)

- the machining is processed on normal and parallel lathe machineries (maximum diameter of the part-1250 mm and lenght 6000 mm)

- the machining can be performend also for big tools, in which case we use the carousel vertical lathe machine(maximum diameter of the part-4300 mm and height 1200 mm)

Stamping

For stamping, we use machineries with the following manufacturing techniques:

- working zone(effective dimension of the work station);

- maximal thickness of the metal sheet-plate-6,4 mm;

- maximum stamping force-180 kN;

- maximum stamping stroke-800 strokes /min;

- maximum bearing stroke-2500 strokes/min

Stamping technology on the numerical control machine tools:

- unfolded complex stamping;

- stamping metal sheet manufacturing machine, high speed manufacturing, punching and threading with numerical control;

- low degree complexity stamping;

- Numerical control stamping machine and low speed manufacture.

Other technological operations

- Milling

- Threading

- Planing

- Slotting

- Welding: steel or stainless steel welding through classical welding action: MIG-MAG and WIG

We manufacture:

- large variety frames production for our partners;

- customization and special application to the machine tools and equipment;

- manufacture of one-off or series products, according to the clients’ specification;

- execution of incorporated systems corresponding to the project.